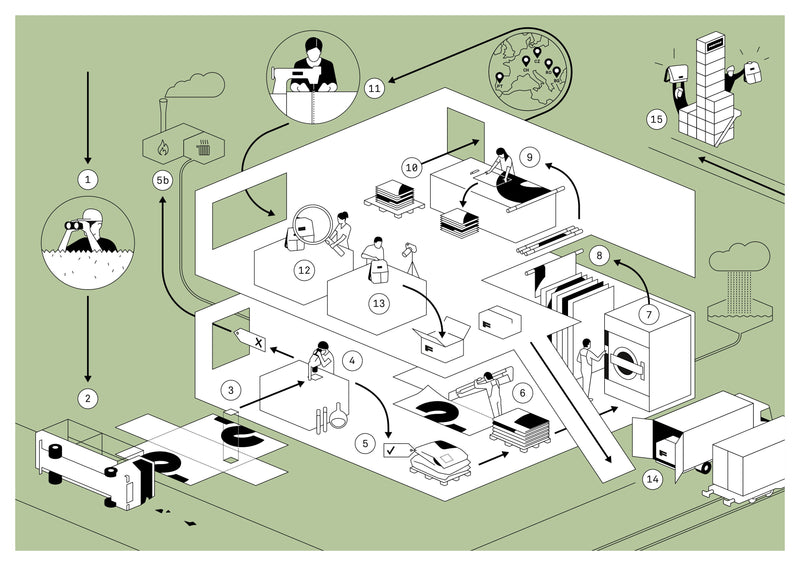

Less Text - More Steps

FREITAG’s one-of-a-kind bag production process for process engineers, flowchart fetishists, icon idolizers and all the other info junkies who prefer visual learning to reading:

1. Truck spotting

2. Tarp removal

3. Extract test sample

4. Testing constituents

5. Confirming that tarp is safe

6. Disassembly

7. Washing

8. Drying

9. Bag design

10. Shipping to sewing partners

11. Sewing

12. Quality control

13. Photography

14. Shipping

15. Sale

Using recycled materials in the supply chain and choosing short transportation routes keeps the carbon footprint relatively low. In 2022, this equated to the equivalent of 3402 metric tonnes of CO2, or approximately 480 flights worldwide. They continue to work actively to further reduce direct and indirect greenhouse gas emissions throughout FREITAG's entire value chain. If you want to know more about the other measures implemented by the brand last year and its future plans, you can find it all in the first FREITAG Impact Report .